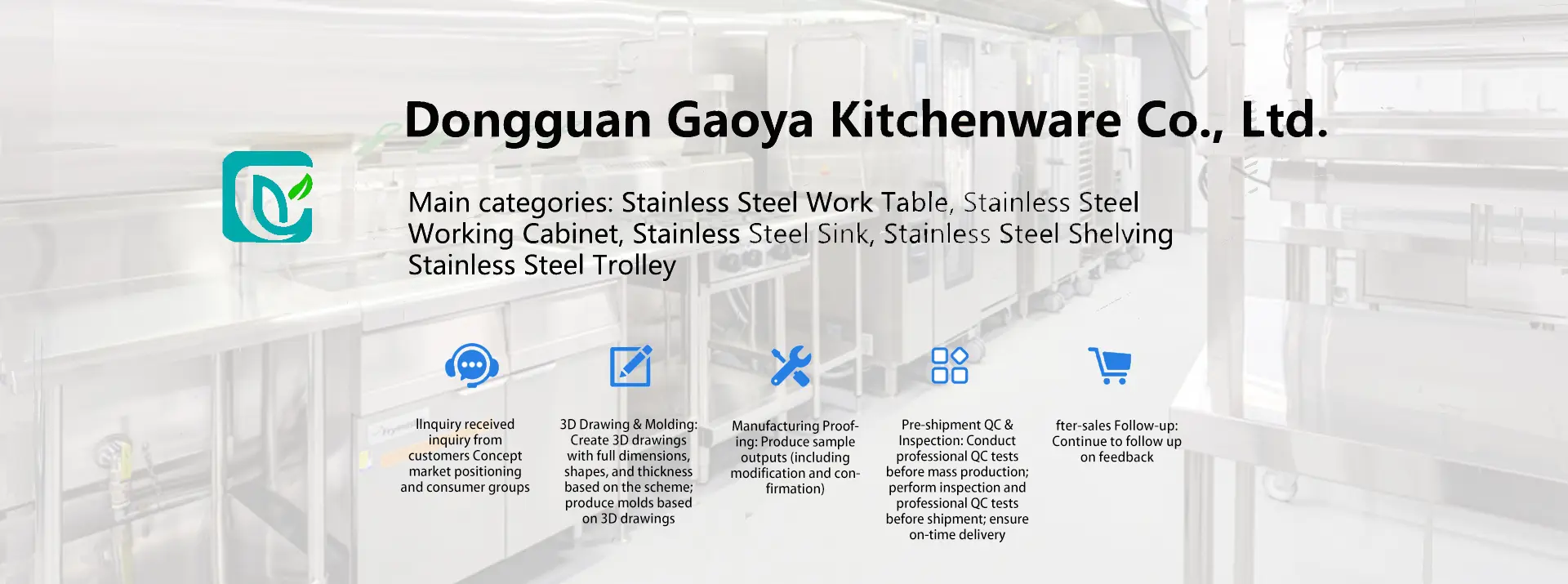

Commercial stainless steel kitchen equipment manufacturer

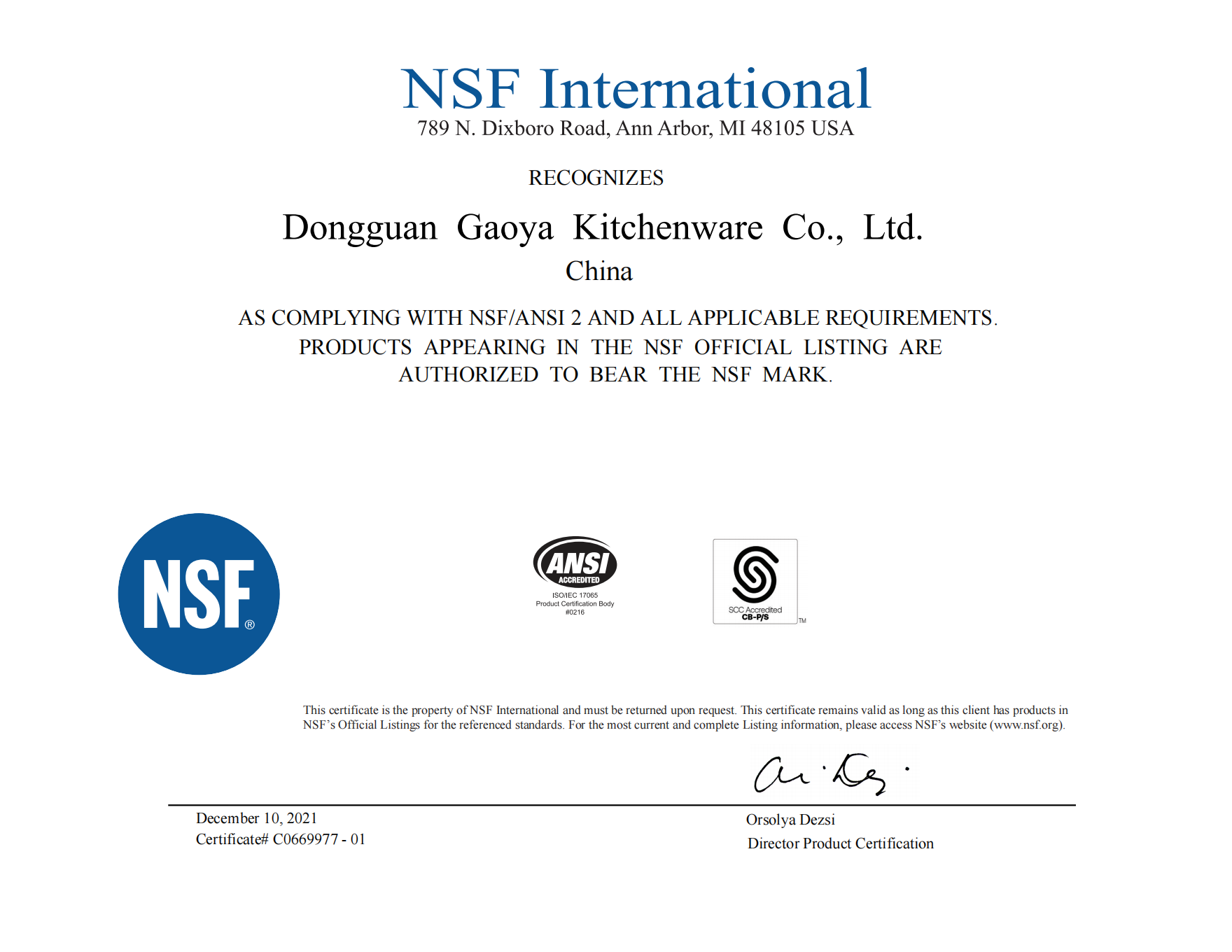

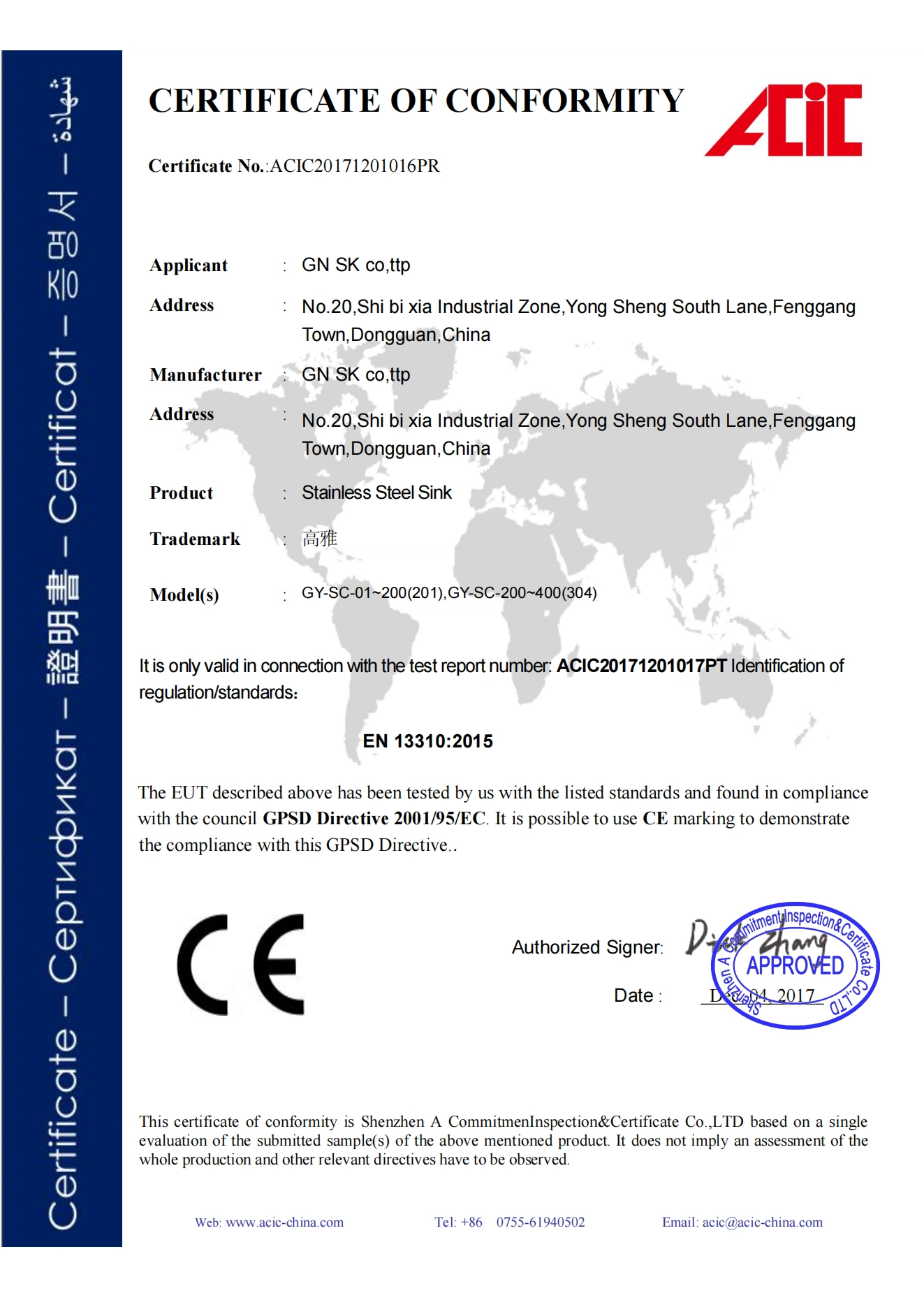

Dongguan Gaoya Kitchenware: 19 years mastering stainless steel kitchenware! Core products: stainless steel work tables, stainless steel sinks, stainless steel cabinets, hotel supplies & food machinery. Our 18,000㎡ factory produces 500,000 sets annually with automated precision. Globally exported, key work tables and sinks are certified to ISO9001, CE, LFGB, and NSF standards. Upholding “Quality First, Customer Foremost,” we welcome global clients to inquire with custom drawings or samples for professional OEM/ODM services!

Year of Establishment

0

Number of employees

0

+

assembly line

0

Factory Size

0

m²

We Provide Quality Not Quantity

Expert Team & Optimized Process Mastery

Success hinges on our skilled workforce and meticulously engineered production workflows. Our seasoned engineers, metallurgists, and production specialists possess deep technical mastery of stainless steel grades (e.g., 304/316), fabrication techniques, and performance optimization. Coupled with lean manufacturing principles and continuous process refinement, we achieve exceptional operational efficiency, minimize waste, ensure on-time delivery, and consistently exceed client expectations for both complex ODM designs and large-scale OEM production runs.

Integrated OEM/ODM Innovation Hub

Empower your brand with our end-to-end custom solution capabilities. Our dedicated, highly experienced R&D team possesses profound insights into global culinary trends, ergonomics, and material science. From initial concept sketches and 3D prototyping to material selection and functional testing, we collaborate closely with clients to transform unique visions into market-ready, innovative stainless steel kitchenware, offering true flexibility and rapid product development cycles.

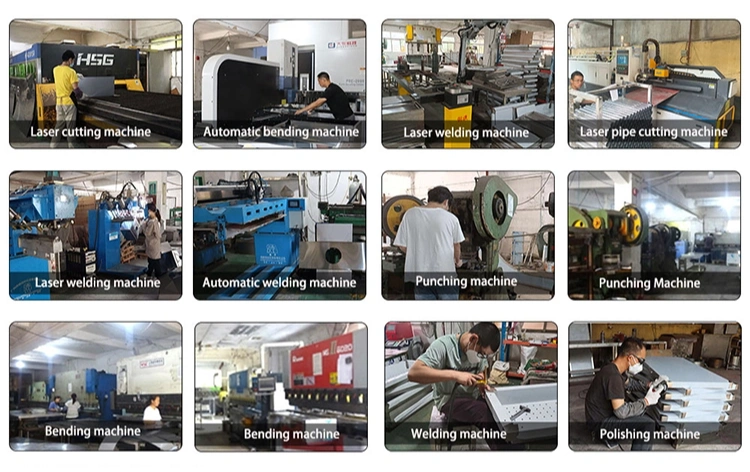

Technology-Driven Manufacturing Leadership

Our investment in cutting-edge, fully automated production lines and proprietary manufacturing processes places us at the forefront of the industry. We utilize advanced CNC machining, robotic welding, laser cutting, and AI-assisted quality inspection systems, enabling unparalleled precision, complex formability, and flawless surface finishes (e.g., mirror polishing, brushed finishes). This technological edge guarantees superior product quality, exceptional dimensional accuracy, and significant cost-efficiency for high-volume OEM/ODM orders.

Decades of Precision Engineering Excellence

Leveraging over [Specify Number, e.g., 19+] years of specialized manufacturing experience, our factory has perfected the art of stainless steel kitchenware production. We combine time-tested craftsmanship with rigorous quality control systems honed over decades. This deep institutional knowledge ensures unmatched consistency, durability, and reliability in every product, meeting the strictest international standards for material integrity, hygiene, and performance that only seasoned expertise can deliver.

FAQ

How do you stay competitive with pricing amid rising material costs?

Our vertically integrated supply chain (raw material → finished goods) and AI-driven production planning minimize waste. We lock material prices for 3–6 months upon deposit, shielding you from market volatility. Annual cost-reduction initiatives keep quotes sharp.

Can you supply products with private labeling for our brand?

Absolutely. We execute turnkey private-label solutions: from brand-centric design tweaks to custom packaging, inserts, and multilingual manuals. All IP remains exclusively yours under signed NDAs.

How do you manage logistics and shipping costs? A: We optimize costs via consolidated container

We optimize costs via consolidated container shipments (FCL/LCL) and partner with DHL/FedEx for air freight. You select Incoterms (FOB, CIF, DDP). Door-to-door DDP solutions include customs clearance in the US/EU/UK/SEA.

Do you offer dropshipping or FBA (Fulfillment by Amazon) support?

We provide white-label packaging, barcode labeling, and FBA prep (including poly bagging, suffocation warnings). Shipments can be routed directly to Amazon FCs, Walmart WFS, or your global warehouses with full documentation support.

What is your production lead time from order confirmation to shipment?

Standard items: 15-20 days. Custom ODM orders: 25-30 days (including prototyping). Urgent orders (<30 days) attract a 10–15% premium. We provide weekly production updates via your preferred channel (Email/WhatsApp/ERP).

Can you handle complex custom designs (e.g., unique shapes, logos, packaging)?

Yes. Our in-house R&D team uses 3D prototyping & CAD simulations to refine designs rapidly. We offer laser engraving, etching, custom packaging, and IP-sensitive material handling. Prototypes are delivered in 7–10 days for approval.

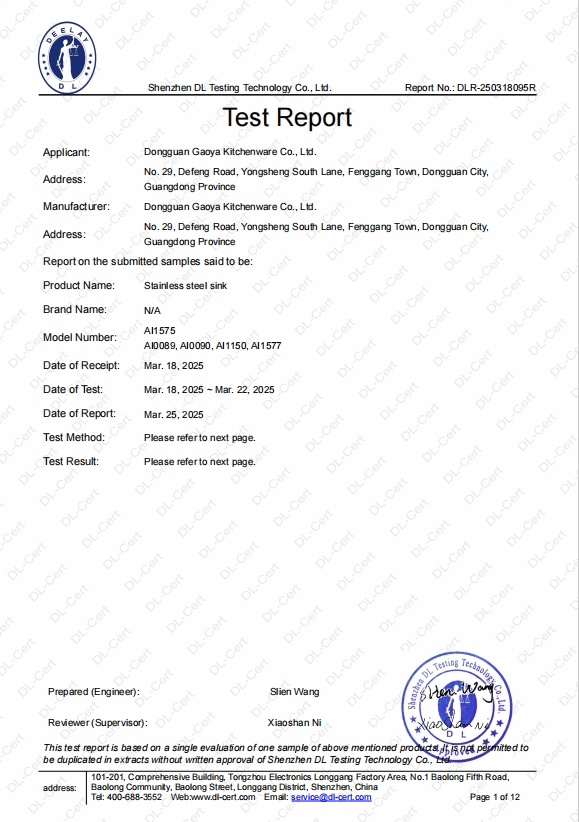

What certifications do your products hold for international markets?

All products meet ISO 9001, BSCI, and SMETA factory standards. Materials are FDA/LFGB/EU 1935/2004 certified (food-grade stainless steel 304/316). We also support CE, NSF, and RoHS compliance upon request.

How do you ensure product quality consistency for large-volume orders?

Each batch of our goods will go through strict QC quality inspection after the production is completed, and we will only pack and ship after the inspection is qualified. (material composition, stress resistance, food safety). We welcome third-party inspections (e.g., SGS, BV).

What is your minimum order quantity (MOQ) for OEM/ODM orders?

We offer flexible MOQs tailored to product complexity. Standard items start at 100 units, while custom designs may require 500–1000 units for cost-effective production. *We provide tiered pricing for bulk orders (5,000+ units) to maximize your margins.

Service Guarantee

Heavy-Duty Export Packaging Solutions

4-layer protection for premium kitchenware: Anti-scratch film → Custom EPS foam inserts → Reinforced 5-ply cartons (edge guards+steel straps) → Optional wooden crates/skids. FBA labeling and container load optimization with packing video proof.

3-Tier Manual Inspection & Instrument Testing

Quality control covers ① Raw material SGS certification ② Manual checks at key stages (welding/polishing) ③ Pre-shipment instrument tests (thickness/pressure/sealing).

Physical Prototyping & Flexible OEM/ODM Process

Leveraging proven manufacturing expertise, we deliver physical prototypes within 10-15 days (from drawings/samples) with phased design freeze approvals. Dedicated teams manage your material specs, logo engraving, and packaging to ensure mass production accuracy.

Factory environment

Exhibition hall

production workshop

welding workshop

Second Department Materials Workshop

gate

warehouse